Today was the Japan Knife Guild annual knife show. It’s the biggest knife show of the year in Tokyo and one of the best. It’s also the last show of the year.

Somehow, I managed to walk away without buying anything. It wasn’t easy, though.

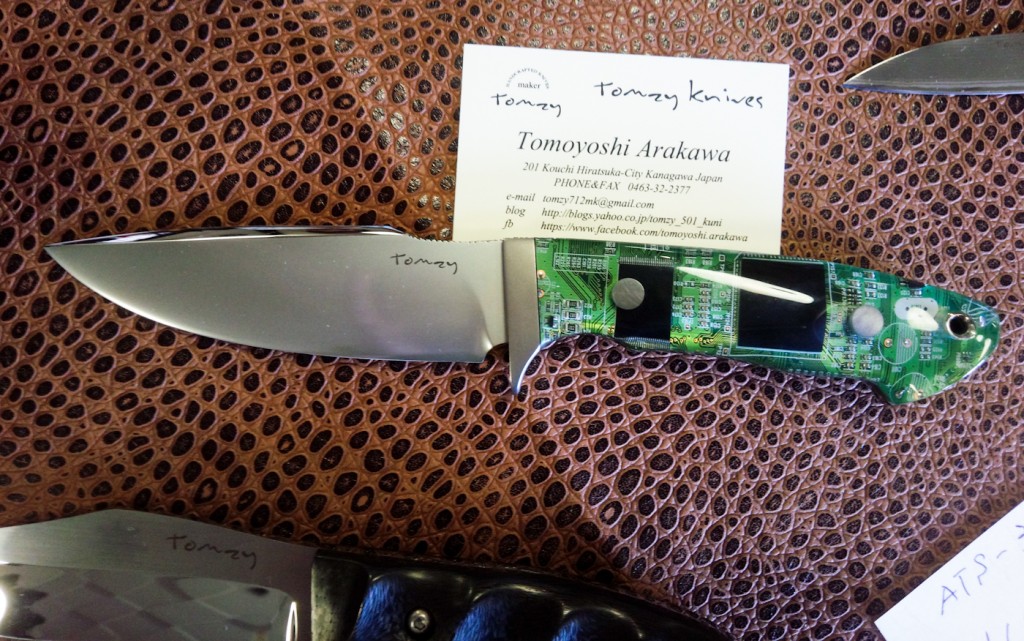

The usual suspects were there with their usual knives and, as in the last show, there was lots of Damascus and a bit of carbon fiber. There were also a few groups of foreigners walking around, and at least one foreigner dropped a bundle of cash on a few knives. There was an attempt to add a few different items. Matrix-AIDA’s table of knife making and knife maintenance goods was a lot larger this time and one woman was even offering handmade paracord bracelets.

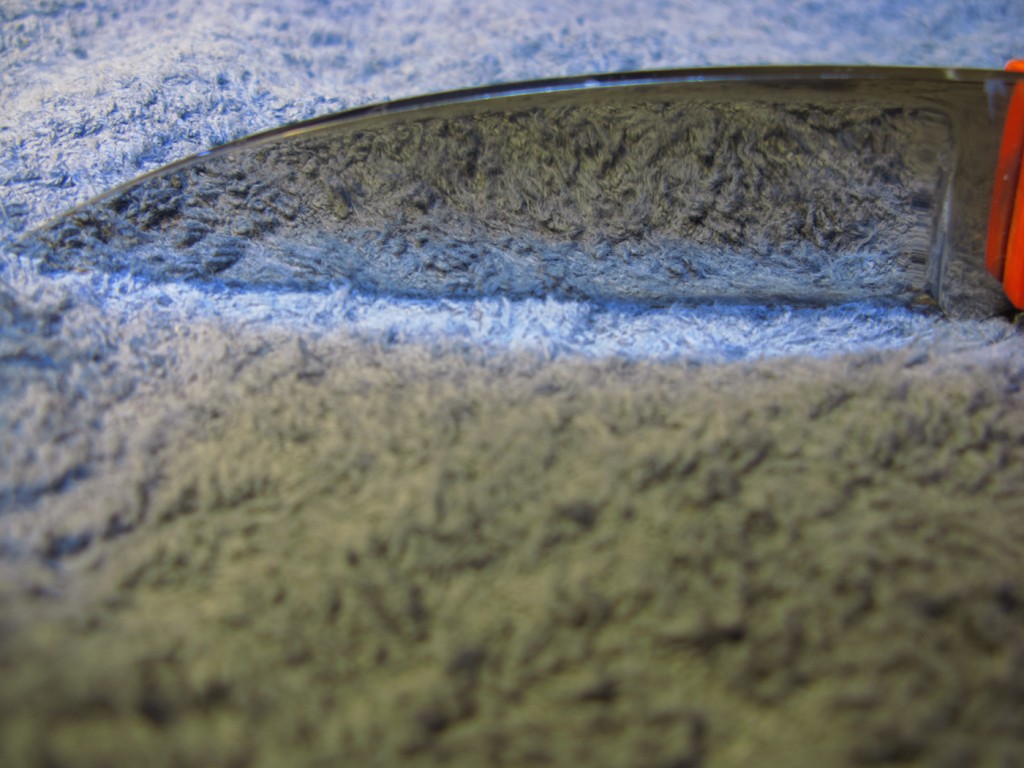

I was greatly tempted by a small carbon fiber and Damascus lockback from To-un Ihara. The discussion with the devil over my left shoulder sounded a lot like an old Jack Benny routine:

Devil–The knife or your wife. (pause) (longer pause) I said the knife or your wife.

Me–I’m thinking. I’m thinking.

Doll from Saw (suddenly appearing)–Live or die. Make your choice.

I opted to pass this time, but I’ll save up and hope it’s still available in February when the cycle of knife shows starts again.

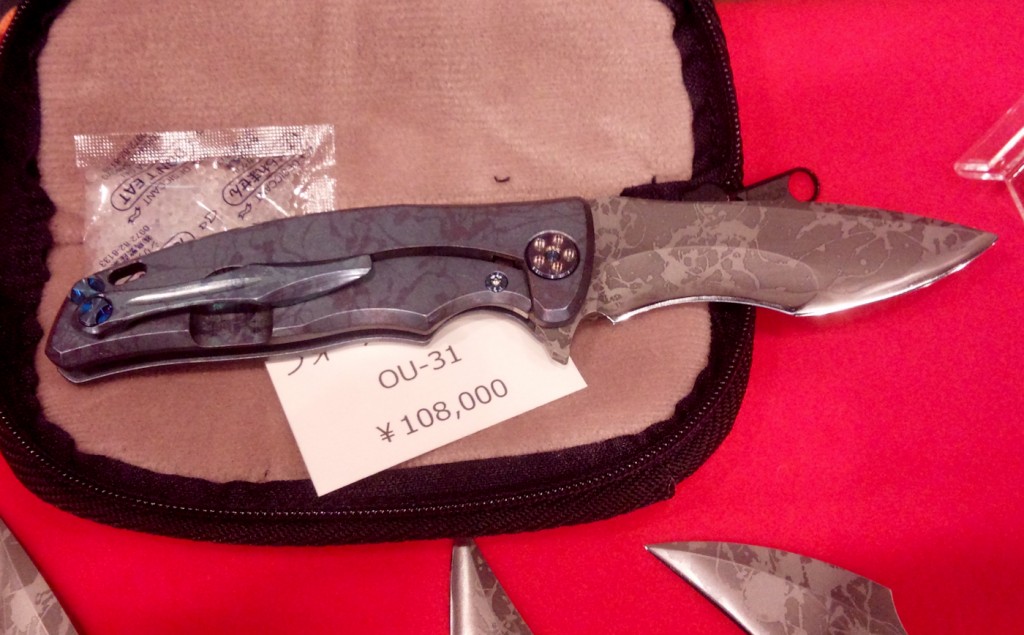

The other star of the show was the first folding knife from Kiku Knives. Kikuo Matsuda typically makes hefty, overbuilt fixed blades for people in the military and people who like to pretend they are in the military. However, as the flipper knife market in the USA is huge, he appears to be attempting to enter that lucrative market. His first attempt was pretty good, even if it’s not really my style.

Despite having a thick, heavy blade with most of its weight near the tip, it flipped open well and felt well balanced. He’s also put a lot of detail in the pivot pins and the clip. I’m not a huge fan of his acid washed blades and don’t see how this could be used for anything other than stabbing stuff, but it’s a cool knife. Not $904 dollars cool, but it has possibilities as a collectors’ item. I should also add he didn’t seem that keen on making another one.

I’m already looking forward to next year’s shows. The first two and the last are usually the best and, therefore, the most dangerous to the wallet. I’m hoping for something different, though, next year. It often seemed as if the same show was repeating itself a few times through out the year.